Innovator: How Passion & Perseverance Led Dwight Wiedrich to Revolutionize Manhole Adjusting Rings

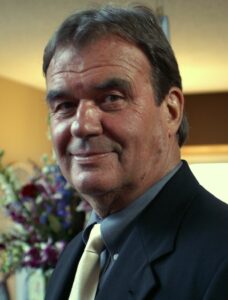

It’s one thing to find your passion in life and use it as a driving force for decades. It’s another to maintain that passion long after others would have felt fulfilled and changed course. No one would have questioned Dwight Wiedrich if he would have moved on to other ventures or simply kicked back and relaxed.

But to Wiedrich, there aren’t many things that can compare to waking up in the morning and pitching the product he invented that revolutionized an industry.

Many individuals in their late 70s would have long been retired. But on the cusp of Wiedrich’s 80th birthday, he found himself still going to work at the company he founded nearly 30 years prior. His company, Ladtech, Inc., reinvented the manhole adjusting ring and revolutionized the underground industry. Ladtech’s high-density polyethylene (HDPE) manhole adjusting rings solved many problems that had long been associated with traditional concrete manhole adjusting rings.

The Ladtech system is used in municipalities across the United States, as well as in Canada and the Bahamas. But unlike those instant success stories of innovators whose products came together quickly and immediately changed the industry, Wiedrich’s story is one of patience, perseverance, and a drive to achieve a dream.

The Thrill of Innovation

Wiedrich’s decades-long career in the underground industry began in the concrete sector — ironically, the sector he would later disrupt with his invention and the establishment of Ladtech. In the 1970s and 80s, he worked for a precast company in Minnesota and was involved with many innovative projects. This allowed him to meet many engineers throughout the state and form relationships that would prove to be beneficial down the road.

Wiedrich’s decades-long career in the underground industry began in the concrete sector — ironically, the sector he would later disrupt with his invention and the establishment of Ladtech. In the 1970s and 80s, he worked for a precast company in Minnesota and was involved with many innovative projects. This allowed him to meet many engineers throughout the state and form relationships that would prove to be beneficial down the road.

Eventually, Wiedrich went to work for another company armed with experience and knowledge that gave him confidence as a problem-solver. He always found himself looking for ways to do jobs better.

One of Wiedrich’s successful innovations involved a junction box that supplied electricity to the street and traffic lights. The existing epoxy-coated box was heavy — around 1,000 pounds — and deteriorated over time. Its size meant that when repairs or replacements were necessary, the city would need a backhoe to dig it up and lift it.

The company Wiedrich worked for had a PVC pipe division, and he had the idea to modify a piece of pipe into a tub to house components. At 100 pounds, its smaller and more lightweight nature meant installing and accessing it was less disruptive. A hole created by a drill was all that was needed. And being made with PVC meant it had a longer lifespan. It took some time to get the transportation department to buy into the new solution, but they eventually came around to the change.

Not long after, Wiedrich was approached with a request that would change the course of his life.

A New Approach to Manhole Adjusting Rings

In 1988, a salesman approached Wiedrich to see if he had any ideas to improve existing concrete manhole grade rings. The rings that form the chimney section are made of concrete and mud with casting on top. They are just 2 inches thick and have no ASTM designation. This means there is no industry standard for the type of mix used — every company can use whatever mix they want.

The problem with concrete rings is that they deteriorate as a result of traffic impact, the freeze-thaw cycle, and corrosion caused by hydrogen sulfide gas (H2S). There also isn’t a great way to achieve the necessary slope with concrete rings. Contractors need to use rocks — Wiedrich has also heard of examples of using baseballs and even shoes — to slope the rings. However, this approach is susceptible to point load failures. And for contractors, the heavy rings are difficult to install.

Convinced that he could come up with a better solution, Wiedrich accepted the challenge. He set out to reinvent manhole adjusting rings.

Overcoming Challenges

It’s simple enough to say you’re going to build a better mousetrap. However, actually doing it isn’t so easy. Wiedrich found this out as he tackled the manhole ring dilemma. He knew he had to develop a product that was similar in price to concrete rings. It didn’t matter how much better an alternative solution was, if it was drastically more expensive, municipalities wouldn’t go for it.

Wiedrich and a friend who worked in the Styrofoam business attempted to make a solid Styrofoam ring, but that wasn’t the answer. He then turned his attention to plastic, creating a prototype that consisted of 12 pieces dovetailed together — a solid, one-piece ring would be too expensive. At this point, he knew plastic was the avenue to pursue. But how would he bring it to fruition?

Luckily, Wiedrich’s boss at the time knew someone in the plastic business, so Wiedrich hired him on an as-needed basis to try different designs. They needed a non-solid, plastic ring that could withstand weight and meet ASTM requirements in order to prove better than concrete. They trialed more than 70 different designs before they began to produce anything close to what could potentially go to market.

Challenges Wiedrich would need to overcome later included finding the proper caulking material for the rings and learning about consistent color. He would eventually find that C990 Butyl Caulk was ideal for the rings because it sticks to both plastic and concrete. Through trial and error, it was discovered that the rings — made from recycled plastic — could be impacted by UV rays and eventually become brittle and crack. The solution was using a UV-protected black colorant and foaming agent, which resists UV damage for decades.

Building Ladtech

Wiedrich received a patent for his plastic rings in 1995 and founded Ladtech to start selling them. In 1996, the HDPE rings were tested by American Testing to confirm their durability. They were impacted 1 million times and didn’t fail. By 1997, Ladtech had a complete mold set to be able to offer different sizes of rings.

The company was set to really take off at this point. Using the industry connections he had made, Wiedrich had the opportunity to put Ladtech products into a handful of Minneapolis-St. Paul suburbs. That fall, Wiedrich prepared to give a demonstration to area engineers. On the weekend before the demo, it rained and temperatures plunged, leaving stacks of rings covered in ice.

That Monday, in freezing windchills, Wiedrich had to break up ice to perform his demonstration, which became a humorous but effective demonstration itself. Using a hammer to break off the ice was time-consuming, so he proceeded to bounce the stacks on the ground to get the ice off. It was a good test of the rings’ durability, so he showed the engineers. The impromptu test convinced the engineers and one of them even called it the best demonstration they’d ever seen.

That fall, 22 new manholes were installed that had the Ladtech adjusting rings. The fact that they could easily be installed in an afternoon was enough for the large engineering firm to specify them.

Contractors initially pushed back against the Ladtech rings because they were new and different. But once they started using them, they realized the benefits were undeniable. They saved money, were quick and easy to install, and had a lifespan that greatly exceeded concrete manhole rings. Word began to spread throughout the area about Ladtech.

Wiedrich became a road warrior, spending 35-40 weeks per year going to shows and meeting with people to take Ladtech beyond Minneapolis-St. Paul.

In addition to his work with Ladtech, Wiedrich also was involved with and held leadership positions in many organizations over the years including Minnesota Utility Contractors Association (MUCA), Minnesota Surveyors and Engineers Society (MSES), Ducks Unlimited, and Pheasants Forever. His accomplishments included organizing golf outings to raise scholarship money.

Ladtech Today

Today, Ladtech has DOT approval in all 50 states. The company’s primary market is throughout the United States and Canada, but Ladtech has also shipped products to the Bahamas, Australia, and Europe.

The company is continuing to grow and innovate. And through it all, Wiedrich has been the driving force, maintaining the enthusiasm he had when the idea to revolutionize manhole adjusting rings first came about.

Even when approaching his 80th birthday, Wiedrich hadn’t grown tired of the grind.

“I still get very excited about demos. I can’t sleep,” he said. “It’s mesmerizing. It’s so much fun.”